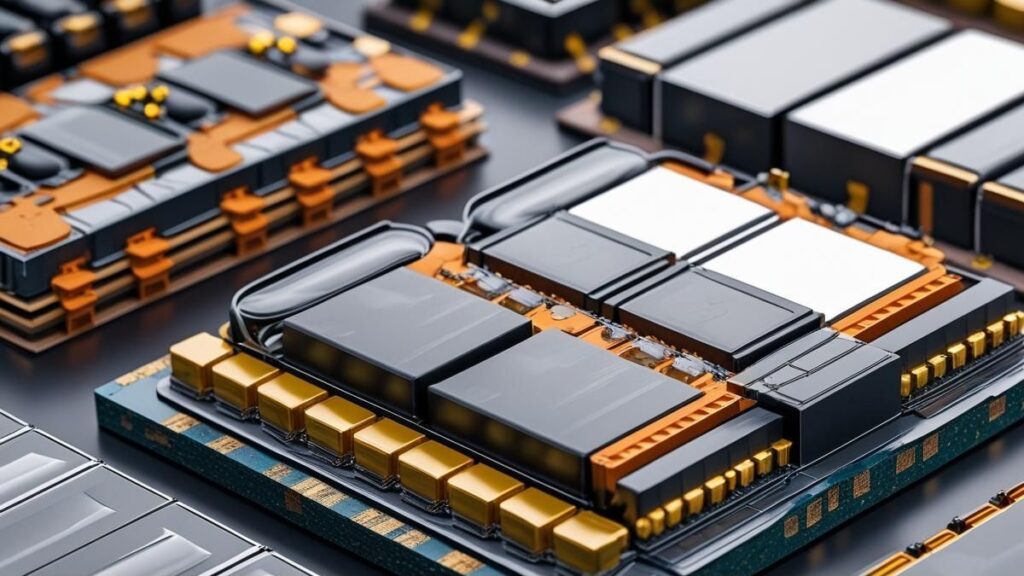

Structural Battery Composites (SBCs) refer to a class of structural power composites designed to provide lightweight energy storage for electrically powered structural systems. Integrating carbon fibers, epoxy resin, or other lightweight, high-strength materials, structural battery composites can store energy in a similar manner to traditional lithium-ion batteries.

While structural battery composites are in the early stages of commercialization, the concept of the technology has evolved over the past couple of decades, driven by advances in materials science, particularly in the fields of composite materials, batteries, and electrochemistry.

Why Structural Battery Composites Matter?

The key driver behind the development of structural battery composites (SBCs) is the potential to accomplish significant weight reductions in various applications.

By removing separate battery enclosures, SBCs offer a path towards lighter and more energy-efficient designs, particularly appealing in industries where weight is a critical factor. Structural Battery Composites can also lead to diversity and decentralized energy material supply chains.

Applications of Structural Battery Composites (SBCs)

Since the structural battery composite is in its infancy, the technology holds immense potential for diverse sectors:

Electric Vehicles (EVs): Imagine a vehicle’s body panels can store energy and function as battery components, boosting range and rigidity while lowering overall vehicle weight.

Aerospace: Structural battery composites could redefine aircraft design by enabling energy-storing fuselages and wing structures. This results in significant fuel savings and enhanced performance, potentially enabling all-electric aircraft in the future.

Drones: Structural battery composite (SBC) wings or fuselages could improve drone frames, doubling drone flight times, making it crucial for applications like surveillance, mapping, and delivery.

Structural Battery Composites (SBCs): Key Challenges

Despite their transformative and exciting prospects, structural battery composites have several technical and regulatory challenges that need to be addressed:

- Achieving High Energy Density

- Long-Term Stability and Durability

- Cost-effectiveness

- Regulatory Hurdles

These challenges must be addressed before the widespread adoption of structural battery composites across industries.

Benefits of Structural Battery Composites

The successful development of structural battery composites (SBCs) promises substantial benefits economically and environmentally.

- Lowering manufacturing costs

- Weight reduction of vehicles and aircraft

- Design flexibility

- Reduced material consumption

- Enhanced energy efficiency

- Potential for decarbonization

Key Actions For Future Development of SBCs

To overcome the existing challenges and achieve the full potential of structural battery composites, key actions are needed:

- Multi-functional material design

- Advanced modeling and simulation

- Robust manufacturing processes

- Cross-sector collaboration

- Proactive regulatory engagement

Future Trends

With the rapid development in EVs and aerospace, structural battery composites represent a critical inflection point. The future trends of structural battery composites would be focused on:

- Integration of SBCs with other technologies

- Sustainable and circular approaches

- New architectures and designs

- Collaboration across materials science, design, energy systems and regulatory frameworks

In essence, Structural Battery Composites (SBCs) emerge as mass-less energy storage that represent a significant paradigm shift in materials science, offering a future where electrically powered structural systems not only perform their load-bearing functions but also actively contribute to energy storage.

While challenges remain, continued research, innovation, and strategic collaboration will be crucial in exploring the full potential of SBCs for a more efficient and sustainable future.

Stay tuned to The Future Talk for more such interesting technologies. Comment your thoughts and join the conversation.